Strong multiphysics coupling towards simulation of edible oil hydrogenation in monolith type reactor

Different phenomena control the performance and even selectivity in multiphase reactors. Moreover, a two way coupling between the physics could be expected when physical and/or chemical properties depend on the conversion rate. Hence, this presentation aims to show a methodology to model a monolith type reactor in Taylor flow condition for edible oil hydrogenation, considering viscosity and diffusivity changes along the reactor.

These innovative reactors are made of a heat conductive material scaffold build using additive manufacturing method. The latter includes a few millimeter inner diameter channels, some hosting the reaction thanks to a few microns thick catalytic layer at wall (washcoat), and some allowing the circulation of a coolant fluid. In specific conditions, Taylor flow, consisting in elongated lubricated bubbles and liquid slugs, is displayed in the reactive channels. This characteristic two phase flow is known to enhance gas-liquid mass transfer, which could improve the selectivity toward the desired product: monounsaturated cis fatty acid in this case.

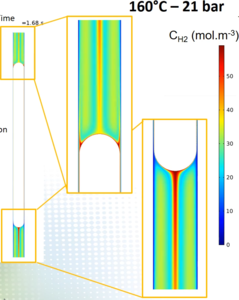

Hence, the entire problem is three-dimensional and locally non-stationary, and exhibits coupling between phenomena (hydrodynamics, mass transport, reaction) intensified by the increased viscosity for partially hydrogenated vegetable oils. The unit cell approach takes advantage of the repetitive nature of the Taylor flow for a fully developed flow : a reference frame follows a unique bubble (far from the inlet and outlet of a given channel) surrounded by two liquid half slugs, and the evolution the pressure, velocity and concentration fields along the reactor using periodic conditions is calculated. Subsequently, this strategy allows a non stationary simulation at the bubble scale to model a characteristic channel and therefore the entire reactor, if isothermicity and uniform gas and liquid distribution at the channels inlet are achieved, thanks to, respectively, sufficient cooling fluid flow in the neighboring channels and adequate inlet technology.

Some hypotheses can greatly simplify the simulation. Bubble shape can be considered ideal (a cylindrical body and two hemispheres at each end). 2D axisymmetric geometry can be used for circular channels. Finally, only the liquid phase is considered since liquid species have a low volatility. The reaction at the wall is modelled as a local flux density, which is calculated knowing local concentrations and the washcoat characteristics.

In-house viscosity and diffusivity models are directly implemented within the calculation to consider the liquid properties evolution along the reactor. The two-way coupling impact is therefore investigated by simply turning on or off these models.